Page you are looking for doesn't exist.

Structural BIM Services

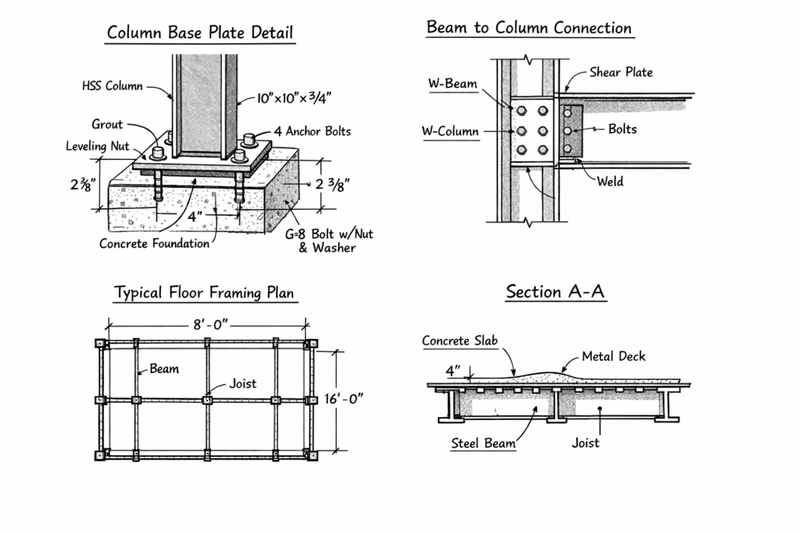

Improve construction accuracy and coordination with Hitech CADD Services’ Structural Shop Drawings Services, delivering detailed, code-compliant drawings for steel and reinforced concrete structures that support smooth fabrication, faster approvals, and error-free installation while ensuring clear communication between engineers, fabricators, and site teams.

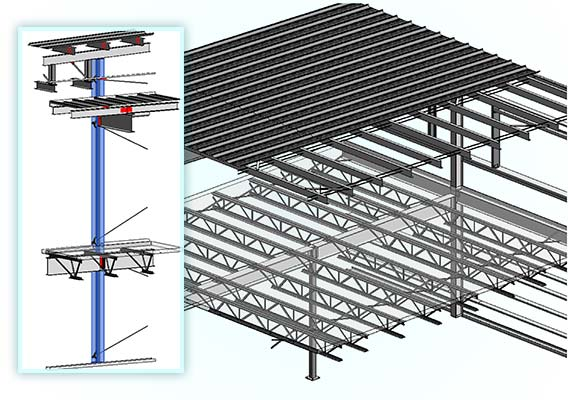

Get comprehensive structural steel modeling that turns your steel design into precise, BIM-ready 3D models with emphasis on accuracy, detailing, and coordination, ideal for Structural engineers, steel fabricators, and contractors aiming to improve efficiency and reduce onsite issues.

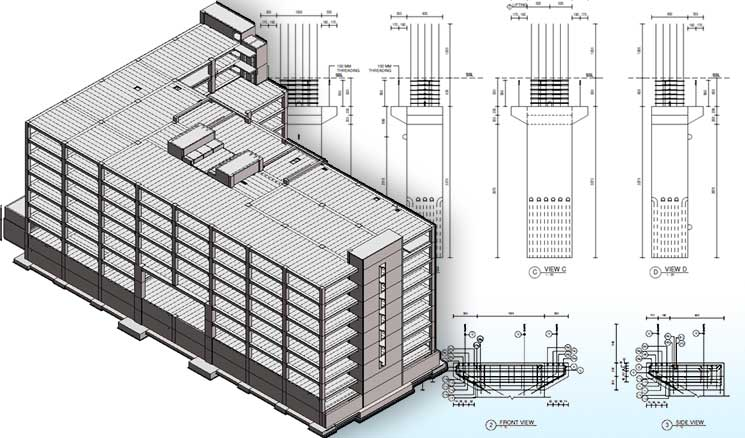

BIM is transforming reinforcement detailing in concrete structures by improving accuracy, coordination, and constructability. With intelligent 3D rebar modeling, clash detection, and automated shop drawings, teams can deliver high-quality outputs that align with structural intent. Discover how BIM-driven workflows reduce errors, speed up approvals, and enhance site execution in reinforced concrete projects.

From 3D modeling to fabrication-ready shop drawings, our precast modeling and detailing services ensure precision, coordination, and faster construction. At Hitech CADD Services, we provide accurate precast concrete models, panel layouts, connection detailing, and production drawings that align with global standards. Our BIM-driven workflows minimize rework, reduce material waste, and improve site coordination for commercial, residential, and infrastructure projects.

Inaccurate rebar drawings cause costly site errors. At Hitech CADD Services, we provide high-precision rebar detailing services that reduce clashes, ensure proper bar placement, and minimize material wastage. Our comprehensive rebar drawings and bar bending schedules improve construction quality and speed up approvals.

Need accurate, construction-ready structural drawings? Hitech CADD Services offers expert structural drafting services that ensure precision, code compliance, and clear communication between architects, engineers, and contractors. From rebar detailing and concrete framing plans to foundation layouts and rebar schedules, we deliver CAD drawings that support faster approvals and efficient construction workflows.

BIM is revolutionizing precast concrete detailing! By integrating Structural BIM technology, engineers and contractors can achieve greater accuracy, improved clash detection, and streamlined fabrication. Discover how BIM optimizes precast concrete workflows and enhances efficiency in construction.

BIM for Prefabrication is changing the game for construction professionals by improving project accuracy, cutting costs, and enabling faster construction cycles. At Hitech CADD Services, we use BIM technology to make prefabrication smarter and more efficient. Explore how we can help your business thrive.

Optimize Precast Concrete Design with Revit! This article delves into essential techniques for using Revit in precast concrete modeling and documentation. Discover how to enhance accuracy, streamline workflows, and precisely create detailed designs. Perfect for architects, engineers, and construction professionals aiming to improve efficiency and reduce errors.

Building Information Modeling (BIM) revolutionizes precast concrete management by enhancing efficiency and quality. BIM creates detailed 3D models for precast elements, optimizing production planning and reducing waste. By utilizing BIM, manufacturers can increase accuracy, minimize errors, and streamline the production process. In this article, you will explore BIM's transformative precast processes, from interference detection to increased efficiency.