Page you are looking for doesn't exist.

Mechanical Design

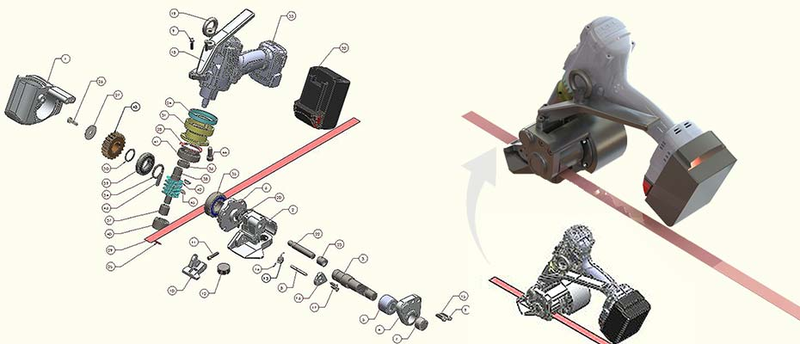

A leading tools manufacturer from the USA worked with Hitech CADD Services to rebuild (reverse-engineer) a pneumatic steel strapping machine prototype that lacked detailed design data. Using 3D scanning, manual measurements, and accurate CAD modeling, HitechCADD created detailed 2D and 3D drawings and checked the design strength through structural analysis. This helped the client cut prototype time by 30%, improve design quality, and get a ready-to-use digital model for future upgrades.

Struggling with DXF handling in SolidWorks? Dive into our detailed guide showing how to import, export, and convert DXF files seamlessly. Whether you're dealing with 2D designs, CNC-ready layers, or converting DWG to DXF, we cover step-by-step workflows, best practices, and troubleshooting tips. Perfect for designers, fabricators, and engineers working across drafting and manufacturing workflows.

From intuitive 3D modeling to real-time performance testing, SolidWorks outshines other CAD software by offering a comprehensive solution for design and engineering challenges. Whether you're in product development, manufacturing, or prototyping, discover why SolidWorks delivers better results compared to traditional CAD tools. It simplifies complex geometry creation, enables detailed 3D modeling, streamlines part assemblies, and supports design validation in a single platform.

Did you know? Poor drafting can lead to a 20-30% increase in material waste and rework! Precision CAD drafting eliminates these inefficiencies by ensuring exact fits and minimizing errors in sheet metal assembly. Learn how!

Design for Manufacturability (DFM) is key to efficient sheet metal production! By optimizing sheet metal design through simplified geometries, minimized forming operations, and improved material utilization, DFM helps reduce costs, enhance quality, and accelerate production. A US-based fabricator saw a 56% reduction in turnaround time using CAD and DFM guidelines from Hitech CADD Services. Learn how smart design choices can streamline your manufacturing process!

Detailed shop drawings are key for contract sheet metal fabricators, enabling accurate quotes, clear design-to-fabrication communication, and error-free installations. Avoid costly delays and ensure quality with well-crafted shop drawings. Discover how Hitech CADD Services supports efficient, high-quality fabrication with precise shop drawings.

Choosing between 2D drawings and 3D models is critical for metal fabricators to ensure precision and efficiency. While 2D works for simple layouts, 3D offers enhanced visualization, reduces errors, and improves collaboration, especially in complex assemblies. The right choice impacts production quality, preventing delays, costly rework, and material waste. Understanding when to use each format ensures streamlined fabrication processes and boosts productivity.

A European retail furniture manufacturer approached us to transform 2D furniture drawings into 3D models with Design for Manufacturing (DFM) strategies. Our services included furniture 3D CAD modeling, design automation, and DriveWorks implementation to streamline production and enhance design efficiency.

Sheet metal fabrication is pivotal in creating high-quality metal parts, ensuring durability and precision. Whether you're in automotive, aerospace, or any other industry, mastering sheet metal design can streamline production and enhance product quality. Learn how advanced techniques in sheet metal fabrication are shaping the future of manufacturing in this insightful article.

Need to share CAD designs across platforms? Autodesk’s DXF files make it simple, especially when working between AutoCAD and SolidWorks. Essential for manufacturing and engineering projects, explore their benefits and best practices in this article.